|

High Paying

US Jobs, Economic

Empowerment

&

Revitalization

of

States through Federal Power |

"Critical Field"

Technology Innovation

&

Maximized Profits on

R&D and Investments |

Prevention of Biochemical

and Nuclear Proliferation

&

Homeland Security

Technologies |

Hand

Held Mine

Detector

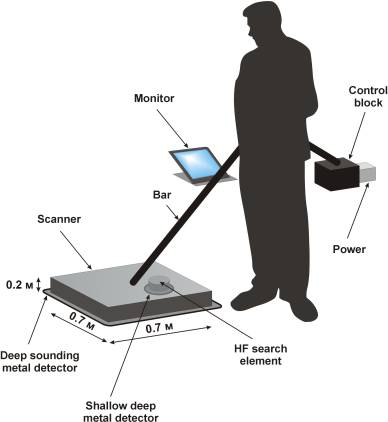

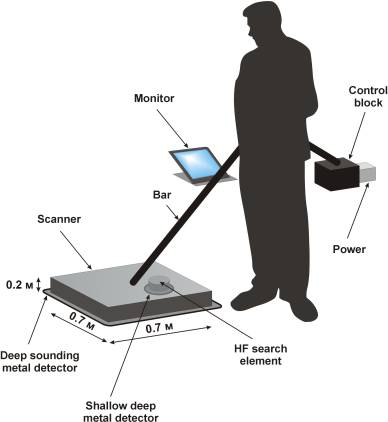

As the above given illustration suggests, the mine detector to

be developed consists of a detection element having both high frequency

(microwave band) and low frequency (induction) channels. Both channels are

employed simultaneously. The operation results of the induction channel are

displayed on the monitor as an image as well. The detection element is placed

inside the square frame of the two-dimensional scanner covered with the

dielectric casing. Images received from both detection channels are processed in

a real-time mode and displayed on the LCD monitor which is mounted on a handle

in front of the operator. The mine detector handle has a counterweight block

accommodating both interface and computer units, as well as a power source.

The minefields are combined as a rule, which means that they include both

antitank and anti-personnel mines. The major part of the mines has round

cross-section view. The antitank mines have diameter of about 300 mm, and the

average diameter of the anti-personnel mine amounts to 75 mm. Some types of the

mines contain practically no metal, which substantially impedes their detection.

In this case the key give-away factor lies in the blasting charges of the mines,

the dielectric properties of which differ from analogous characteristics of the

ground that covers them. Thus, relative permittivity er for the typical

explosives is between 3.5 and 4.0. At the same time dielectric properties of the

ground in the considered frequency range vary within a wide range from 2.6 to

25.0, depending on the composition and moisture content of the ground. The

lowest value of the range is related to absolutely dry sand, which is found in

the desert. In the overwhelming majority of cases er for the ground exceeds the

analogous value for the blasting charge.

MiRascan ground-probing holographic radar that makes it possible to detect

and identify slightly deepened (up to 20 cm) objects by their shape has been

developed in the Remote Sensing Laboratory. The principle of the multifrequency

sounding of the condensed media (construction structures, soils, etc.) was

assumed as a basis of the radar design.

In the initial segment of this work, the mock-up of a wide-span mine detector

MiRascan, which included, in the capacity of a detecting element, a five

frequencies ground penetrating radar receiving signals in two crossed

polarities. The detector's sensor was installed on the cart, which was set in

motion by an operator manually.

In the course of further research, the mock-up of the mine detector MiRascan

underwent modernization. Basic features of it were as follows:

- On the lower flange of the GPR cylindrical antenna, the head of the metal

detector was installed;

- On the upper flange of the radar antenna, a generator metal detector block

was installed;

- On the axes of chassis front wheels of the mine detector the electrical

motors working in the impulse mode were installed;

- Remote control system of the mine detector movement was assembled. The

operator via the remote control box, connected to the cart by the cable of

15 m length, exercises control over the movement of the mine detector.

The radar has five operational frequencies in the range from 1.5 to 2.0 GHz and

transmits unmodulated signals at each frequency. Its signals are received in two

polarizations. Power emitted by the generator on each frequency is switched in

sequence. It amounts up to 10 mW, which provides for the complete safety of

staff. As previously mentioned, the induction loop of the metal detector was

located on the butt end of the antenna of the ground penetrating radar, which

provides spatial coincidence of received images from two channels of the mine

detector. Operating frequency of the metal detector is 2 MHz, and the diameter

of the induction loop is equal to 120 mm. The successive reception of signals on

each frequency and in both polarizations of GPR and from the metal detector is

conducted in the process of scanning the ground surface. The frequency switching

rate is such that it provides for the spatial matching for all microwave images

of the GPR separate frequencies and metal detector image.

The scanning in the lateral direction is carried out at the

expense of electromechanical movement of the SHF device of the radar, and in the

longitudinal direction due to the movement of the entire radar. The scanning

results are displayed in the form of gray scale images on the monitor screen.

Since it is difficult for an operator to perform a simultaneous analysis of all

images on different frequencies, one animated image is formed in which

sequential frames correspond to different frequencies.

The mock-up of the mine detector makes it feasible to survey the lane of

movement 112 cm wide and to display the scanning results on the screen of a

personal portable computer in real time.

The experiments to detect and identify mock-ups of the plastic-cased

anti-personnel and antitank mines were conducted under the full-scale

conditions. The experiments were performed on the special proving ground. The

proving ground had sites with the key types of soils: sand, chernozem, loamy

soil, etc., which ensures wide variation in their dielectric properties.

The mock-ups of the antitank plastic-cased mines of the types of TM-62P3

(manufactured in Russia), TC/6 and TC/2.5 (manufactured in Italy), of the

anti-personnel plastic-cased mines of the types PMN-2 and MS-3 (manufactured in

Russia), as well as of the metallic antitank mines of the types of TM-62M and

PTM-3 (manufactured in Russia) were used in the capacity of the tested objects.

All the mines except the PTM-3 mine had a round cross-section view, and the

PTM-3 mine had a rectangular cross-section.

Wide-span

System for Humanitarian Demining Operations

Introduction.

Our team had

taken an initiative in the development of MiRascan subsurface sounding radar to

enable the operator to detect and identify objects buried under the ground at

low depth (up to 20.0 cm) basing on their shape analysis. The operating

principle of the radar design is based on the method of multi-frequency sounding

of a condensed media (like building structures, grounds, etc.). The method

offered has no counterpart in the world practice so far. (Russians Launch

Anti-Bugging Radar. Microwave Journal, February 1998, Vol. 41, No. 2, pp. 47,

48). The

creators of MiRascan

radar

are Russian Federation Government prize-winners in the field of science and

technology for 1999.

One

of the main problems while liquidating the aftereffects of local conflicts is

mine clearance of the territories that were mined as a result of combat

operations. The special difficulty in the process of humanitarian mine clearance

is presented by the fact that minefields were laid as a rule chaotically,

without compiling proper mine-field records (charts), as well as the fact that

mines with antidisturbance fuses were also installed.

As

a rule, the minefields are combined, which means that they include both antitank

and anti-personnel mines. The major part of the mines has round cross-section

view. The antitank mines have diameter of about 300 mm, and the average diameter

of the anti-personnel mine amounts to 75 mm. Some types of the mines contain

practically no metal, which substantially impedes their detection. In this case

the key give-away factor lies in the blasting charges of the mines, the

dielectric properties of which differ from analogous characteristics of the

ground that covers them. Thus, relative permittivity er

for the typical explosives is between 3.5 and 4.0. At the same time dielectric

properties of the ground in the considered frequency range vary within a wide

range from 2.6 to 25.0, depending on the composition and moisture content of the

ground. The lowest value of the range is related to absolutely dry sand, which

is found in the desert. In the overwhelming majority of cases er

for the ground exceeds the analogous value for the blasting charge.

The

heterogeneities of the surface, as well as a great number of foreign objects in

the ground, especially in the urbanized localities create substantial

difficulties in the mine detection operations. The dielectric contrast of these

heterogeneities with reference to the ground frequently exceeds the contrast of

the plastic-cased mines, which results in an inadmissible level of false alarms.

At the same time, in accordance with the requirements of the UN, the probability

of mine detection should amount to 99.6% at the low level of false alarms. But

these requirements are not met by the existing technical means. Very often the

mine-probing rod and snuffer dogs are the only aids of the sapper.

Description.

The development of the wide

span gears making the most of the spatial filtering to reduce the level of false

alarms is one of the approaches to achieve the set aim. The mock-up of such mine

detector using Russian-made mine detectors of the MMP type in the capacity of

the search elements was designed in late 1980s.

The

new design considers possibilities for the enhancement of efficiency of mine

detection operations that thanks to usage of multifrequency SHF transducers

coupled with metal detector and to generation of the radio images of the terrain

in the lane of movement of a mine detector. An experimental mock-up with the

transducer providing for scanning in two dimensions has been developed, and

algorithms for the representation of information on the display screen in the

form of animated images have been put forward. Proposed methods may find their

use during peacekeeping and humanitarian operations. Fig. 1 presents the

block diagram of the radar MiRascan.

The

scanning in the lateral direction is carried out at the expense of

electromechanical movement of the radar, and in the longitudinal direction due

to the movement of the cart. The scanning results are displayed in the form of

gray scale images on the monitor screen. Since it is difficult for an operator

to perform a simultaneous analysis of all images on different frequencies, one

animated image is formed in which sequential frames correspond to different

frequencies.

The mines were deepened in the ground to the depth of 1 cm for the

anti-personnel mines and to 5-8 cm for the antitank mines. The experiments were

conducted on the two types of soils: heavily moistened sand and heavily

moistened chernozem with turf cover. The soils had the natural moisture content

close to the saturation as the experiments were carried out a day after the long

heavy showers.

|

|

|

Diagram of mines arrangement

in the proving ground

|

Microwave images of mine mock-ups

in the examined lane with sandy soil

|